Magnesium Melting Stent

When it comes to the tiny scaffold-like stents inserted to unblock the clogged arteries of heart disease patients, the stakes could not be higher.

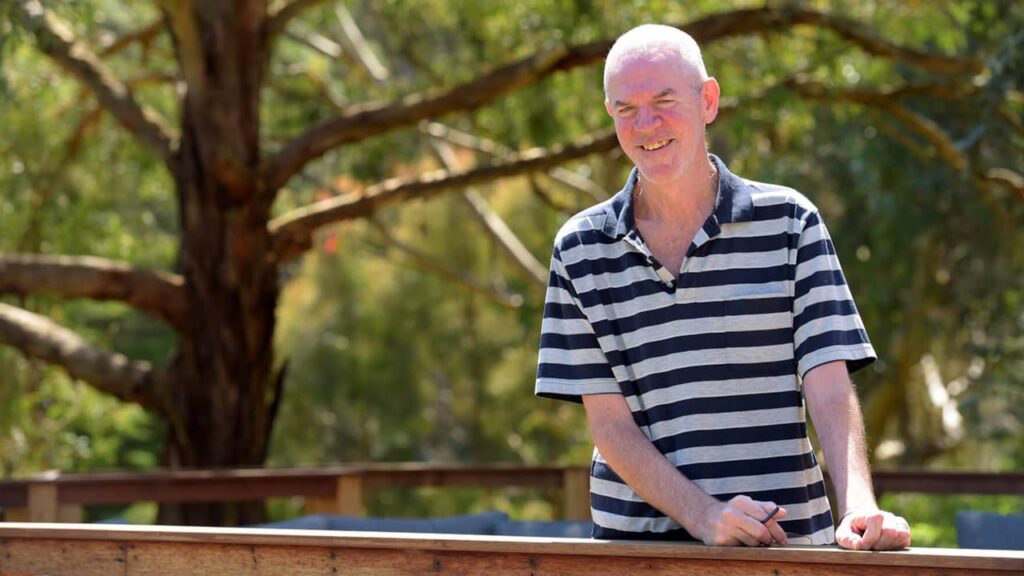

Professor Peter Barlis has performed the first operation in Victoria using the new ‘melting’ stents, which are made from biocompatible magnesium metal.

Developed by German medical device company BIOTRONIK, the new the magnesium stent dissolves over time and is reabsorbed as an inert substance, just like the magnesium nutrients that already exist in our bodies.

Professor Barlis said this new type of stent reduces risk of inflammation and scar tissue that can block the artery again. And by the time the stent dissolves, the artery should be fully healed and stay open.

“The magnesium stent is attractive because it affords us increased strength over the polymer stents and dissolves in just 12-18 months rather than three years or more,” Professor Barlis said.

Professor Barlis is working with the University of Melbourne School of Engineering to develop next-generation stents that can be 3D printed to a patient’s exact specifications, or could deliver medicine to the heart using nanotechnology.

“Our vision is to improve these devices by making them thinner, which may mean looking at other materials or potentially using nanotechnology to use stents as platforms to release drugs over time to where they are most needed – in the artery itself,” he said.

“We could potentially use such an advance to target cholesterol in the artery to stop the build-up of the plaque that eventually causes blockages.

“It could also be a way of delivering drugs such as blood thinners for example, without having to rely on patients to keep taking their medication.”

Story by Andrew Trounson / Kathryn Powley